Smart Platform Solutions

Smart Platform Solutions

|

- Customer Pain Points

- Programmatic Architecture

- Program Value

- Implementation Process

Contact us

Integrated centralized control is not in place

Weighing room, vehicle dispatching, yard monitoring, loading, personnel monitoring and other links operate independently, lack intelligence and interaction, do not build intelligent Internet of Things management and control platform to collect dynamic data in real time, lack intelligent analysis, centralized control, intelligent alarm, intelligent decision-making and automatic execution intelligent system.

Weighing management is backward

There is no pre-management for loading and unloading drivers, queuing on the spot with paper coal bills or IC cards, long queuing time of vehicles, low weighing efficiency of drivers, affecting road traffic.

Manual inventory data lag and error prone

There is no real-time linkage between inventory and weighing room, lack of automatic inspection system, inventory data can not be dynamically presented in real time.

Monitoring relies on manual work, and automatic detection and identification have not yet been realized.

The detection of foreign bodies at the bottom of the vehicle, the detection of foreign bodies in coal, the detection of partial load of heavy vehicles, the copying of carriage numbers, etc. are still manually operated, with low efficiency and safety risks.

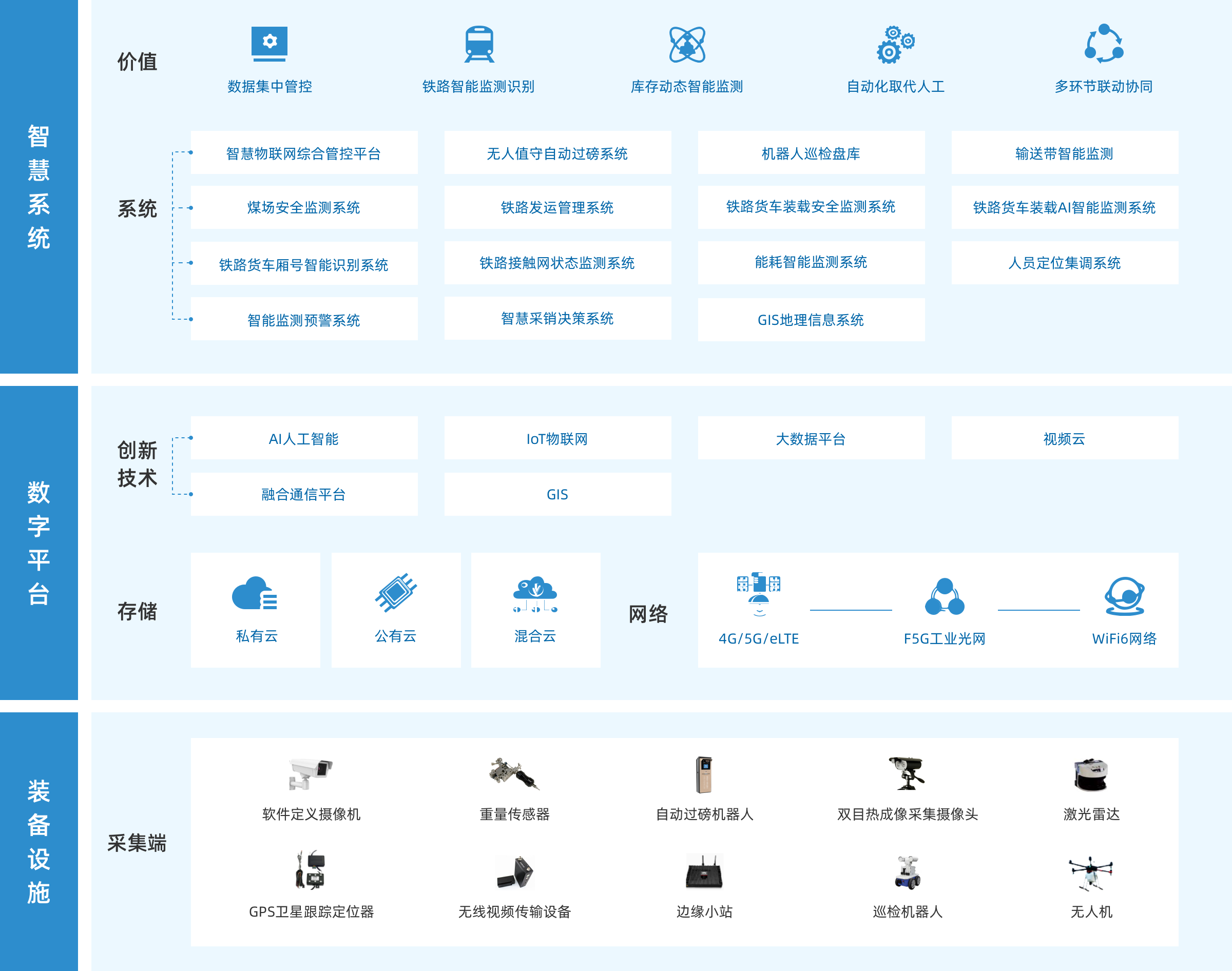

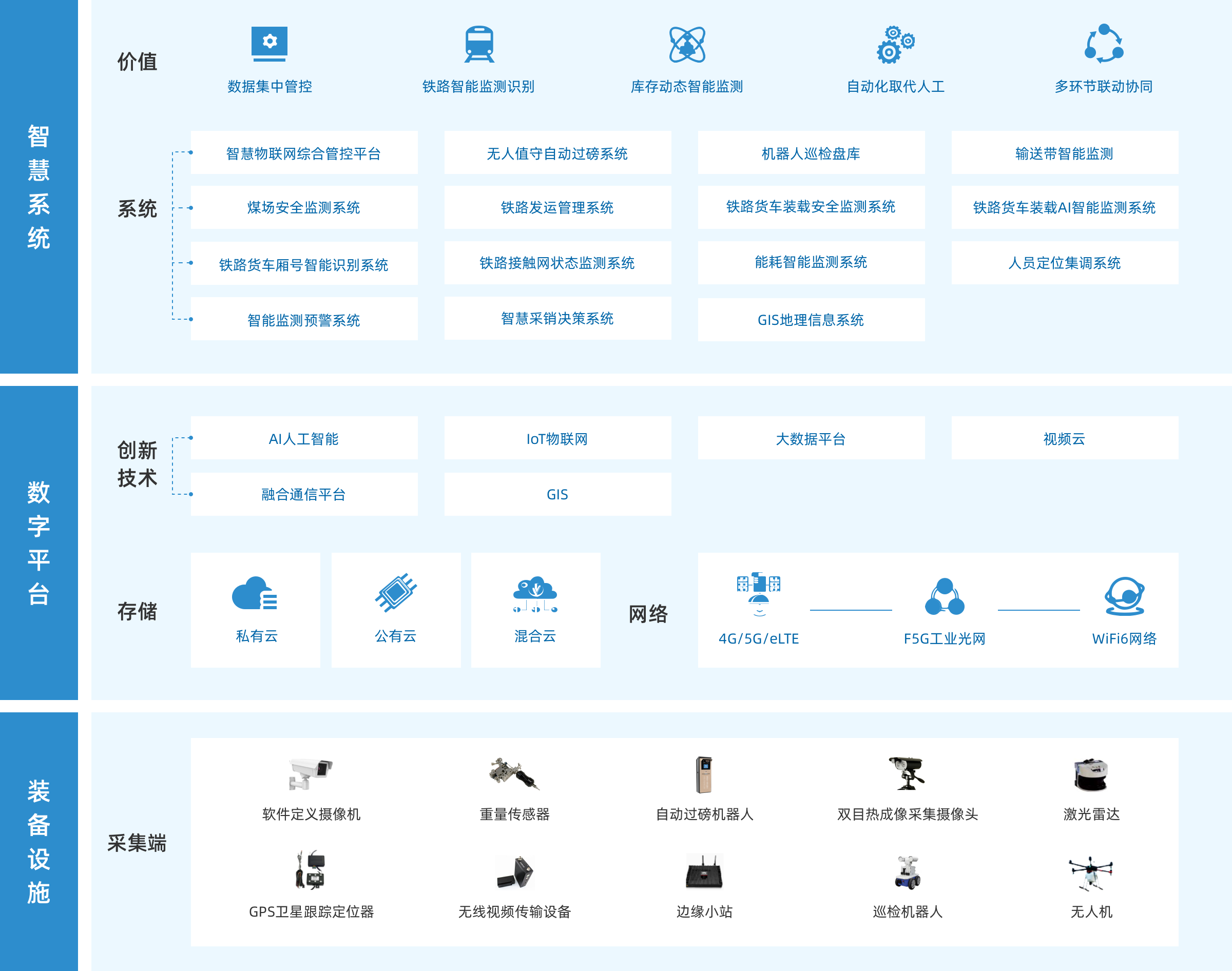

Programmatic Architecture

Relying on the AI+IoT platform capabilities of Zhaomei, build PaaS platforms and multi-scenario SaaS applications that meet coal mining enterprises

Integrated centralized online control

The data of all links such as weighing room, vehicle dispatching, yard monitoring, loading and personnel monitoring are concentrated on the Internet of Things management and control platform, breaking the data island, centralized management and control, flexible combination analysis and panoramic view of platform operation status.

Improve shipping efficiency and human efficiency

The weighing room realizes unmanned, automatic weighing, intelligent scheduling, real-time inventory update, effectively reduces labor costs, reduces truck weighing time by 90%, and reduces vehicle queuing time.

Intelligent monitoring and identification, intelligent alarm to ensure timeliness

Visual monitoring of personnel violations and irregular operation behaviors; intelligent detection of foreign matters in vehicle bottom and coal pile, automatic identification of carriage number, real-time monitoring of equipment operation status, and intelligent alarm. It can effectively improve the detection and identification accuracy, improve efficiency and ensure safety.

Global wireless coverage of stations

Through 5G, eLTE, Wifi6 and other wireless network layouts on the platform, functions such as cluster communication, sensor data acquisition, equipment data transmission and control, on-site video backhaul, and intelligent vehicle scheduling are realized.

On-site visits to investigate needs

Provide customized solutions

Sign the contract and make the down payment

Installation, deployment, commissioning, training

Customer acceptance, payment of final payment