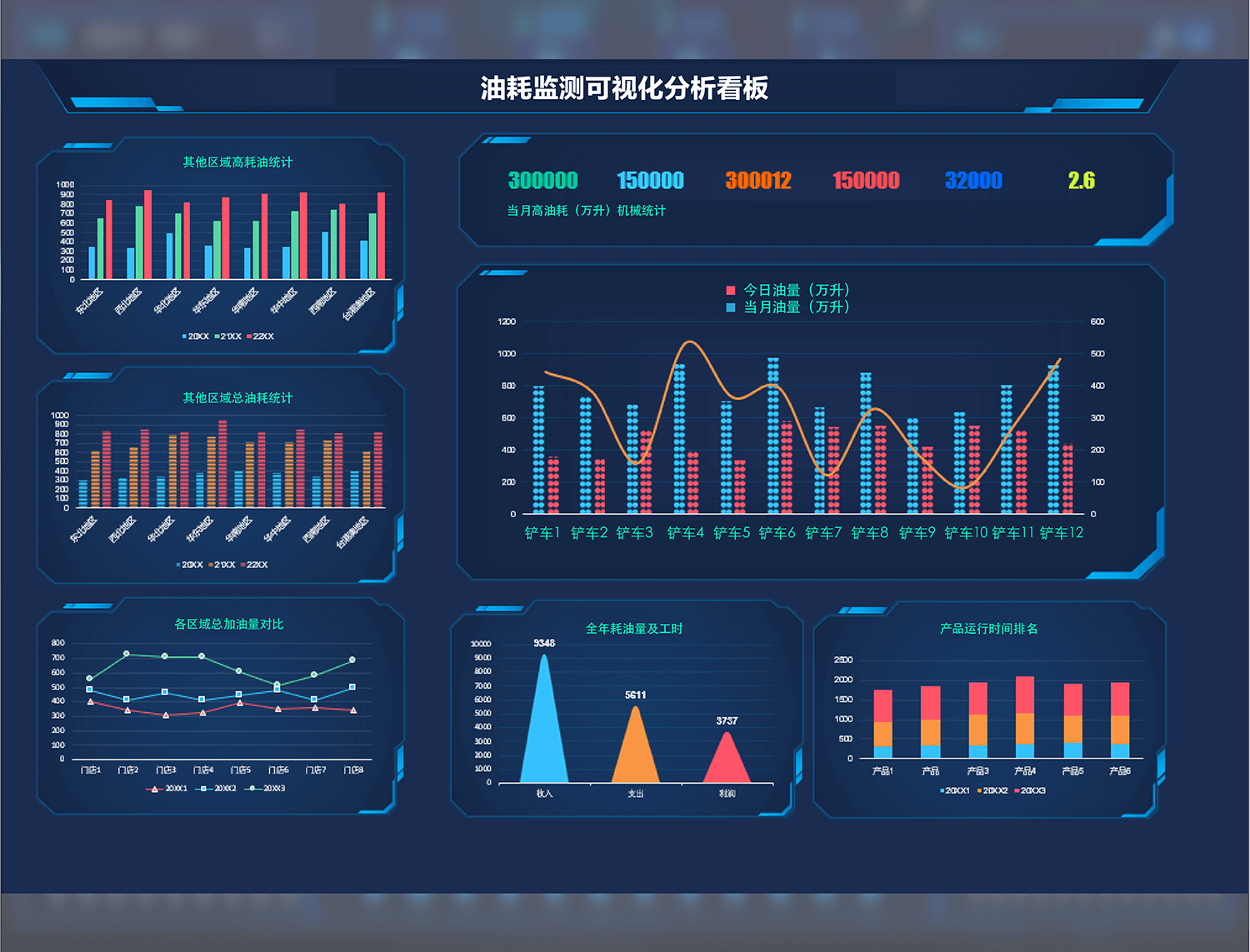

Energy Consumption Monitoring System

The energy consumption monitoring system is a system that provides data for the monitoring and control of power consumption, fuel consumption and other energy applications.

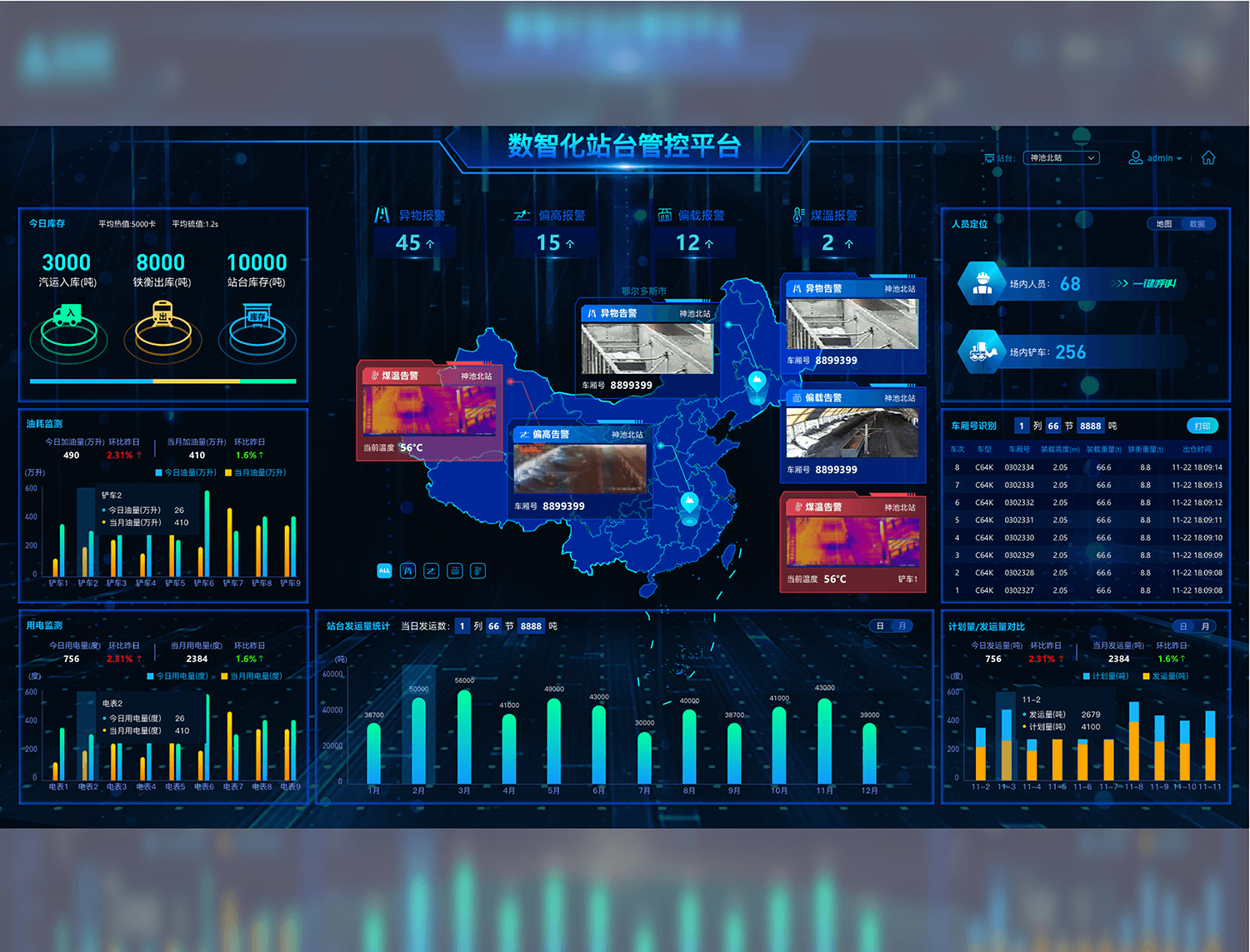

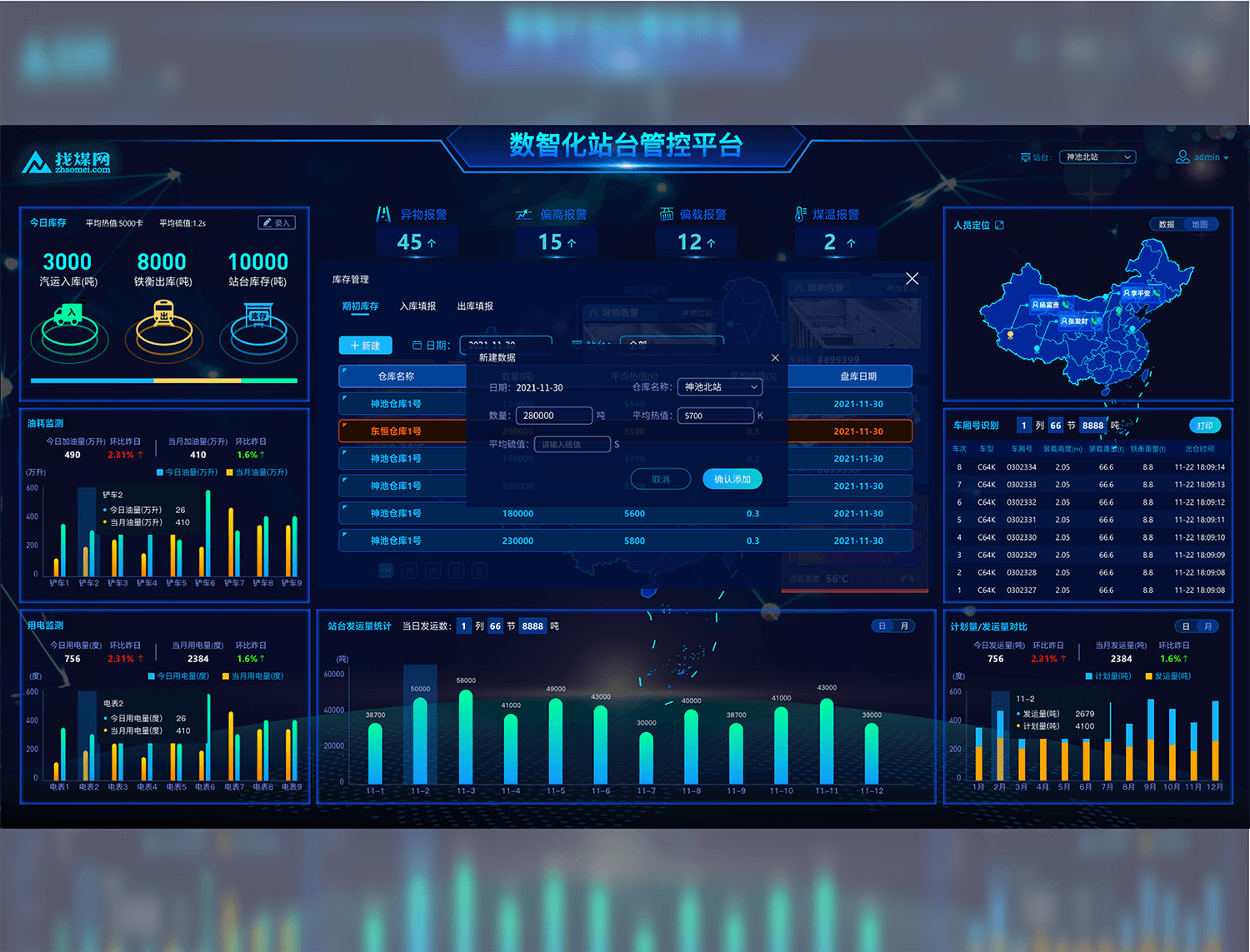

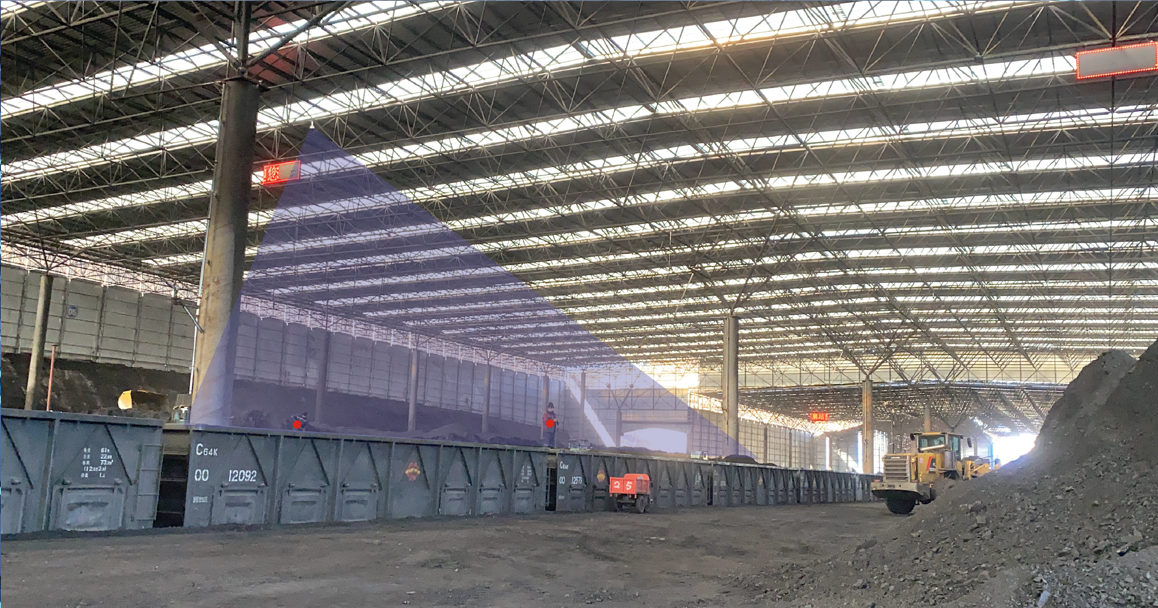

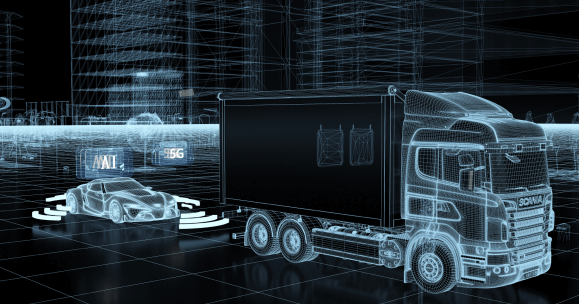

It uses advanced Internet of Things technology to realize intelligent identification, tracking, monitoring and management of equipment, and is used in enterprises.

Monitor energy consumption in real time to save energy, avoid waste, and reduce personnel costs.

- Extensive monitoring functions to reduce energy consumption in all aspects of the enterprise

- Fuel consumption management

- Automatically collect the refueling amount and fuel consumption of various types of machinery to promptly discover and optimize high-fuel-consuming machinery

- Track management

- Real-time collection of the location and trajectory of machinery and personnel, combined with fuel consumption, working hours and other data to achieve refined management

- Working hours management

- Monitor the operating status of equipment, automatically count manual working hours, and calculate effective working hours

- Power consumption monitoring

- Monitor and manage the power consumption of equipment, automatically collect and analyze power consumption data to estimate future energy consumption, and achieve energy conservation and emission reduction.

- Online 24 hours a day, real-time data reporting

- Real-time monitoring throughout the day to avoid equipment "long standby"

- Timely discovery of unused but running equipment to avoid energy waste and intelligent energy-saving management and control

- Detection frequency 5-10 minutes/time

- The detection frequency and time can be customized independently, and high-frequency detection can avoid equipment failure and outage.

- Automatically alert when encountering problems

- Abnormal automatic alarms are sent to the background to facilitate management personnel to handle them in a timely manner.

- Reduce detection work, 1 person easy operation and maintenance management

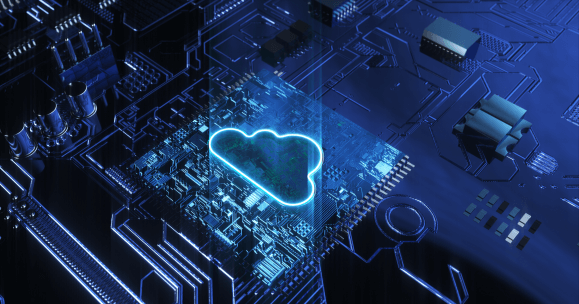

- Rapid collection of monitoring data

- Automatically collect data within the monitored range and store it in the background for review at any time

- Energy consumption data transparency

- Automatically analyze and compile collected data, and generate reports and statistical charts

- Easily identify equipment high consumption issues

- Compare the energy consumption of the same equipment and quickly identify equipment problems through data reports

- Digital and intelligent management

- Centralized intelligent management and control of machinery/people/equipment/energy, management of multi-dimensional data integration/analysis/linkage/AI, etc.